InStep - Help

Inflate Shell Surface

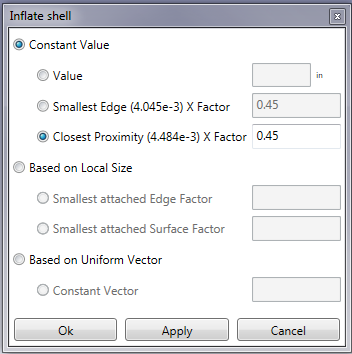

Upon selecting a body and clicking the Inflate Shell tool button, the above tool box opens up. The tool allows a given surface to be thickened into a solid by means of a few different methods and parameters. The basic process is that the surface gets copied and offset along a vector and then stitched together with the source surface.

The vector by which each vertex point is offset is defined by this dialog. The basic options are:

- Constant value

- Based on Local Size

- Based on Uniform Vector

The constant value assigns a distance to each vertex normal vector. The normal at the vertex is defined as the average of the surface normals that surround the point. By using a simple value, each vertex is offset by this constant value. Basing it off the Smallest Edge allows the global edge lengths to be considered and applies a factor to the smallest and uses this distance. The closest proximity option is similar but calculates proximity of vertices and uses this distance together with a factor. Picking the smallest value is usually a safe approach though some issues can still arise if the surface has sharp angles.

Based on Local Size allows variation within the surface offset and each of the vectors is based on either the length of the edges or based on the size of the facets.

Using a Uniform Vector, allows all the offsets to occur along one principal direction, irrespective of the local normals. This option should only be used for cases where the thickness along a direction is to be constant.

Once the surfaces are offset and stitched together, the resultant data is reloaded and checked for issues. If issues occur, the process should be restarted and smaller offsets chosen or the underlying data refined in areas where issues occur.